SIGSeal ─ Tyvek® Coating Technology

Self-developed formula

Combines breathability with excellent sealing properties

Offers superior humidity and condensation resistance

Remains free from yellowing over time

Medical Device Challenges with Tyvek® Coating

Customers in the medical device industry face several challenges with Tyvek®-coated paper. These issues include:

- Poor sealing after adhesive application, resulting in packaging with weak tensile strength.

- Materials difficult to tear, releasing paper fibers when opening the packaging.

- Bags bursting due to excess gas pressure after autoclave sterilization, causing visible ruptures.

- Subpar adhesive quality leads to incomplete melting during heat sealing and improper closure.

- Yellowing over time, diminishing paper aesthetics and quality.

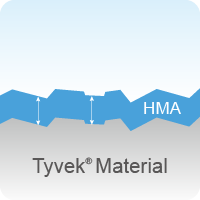

- Irregular adhesive application on uneven Tyvek® substrates, causing wrinkling and disrupting manufacturing processes.

These challenges significantly impact customer satisfaction as they fail to meet sterile barrier requirements.

Poor sealing

Subpar adhesive quality

Bursting bags

Paper fibers

Yellowing

Wrinkles

SIGSealTM Advantages

SIGSealTM , SIGMA Coating Technology on Tyvek® leverages eco-friendly, water-based adhesives developed in-house. This patented formulation enables independent perforation while preserving Tyvek®’s inherent breathability.

In addition to our unique adhesive formulation, SIGSealTM employ Non-Contact Coating technology for precise adhesive application to Tyvek® substrates. This enhances packaging strength and mitigates paper fiber issues associated with inadequate tensile strength.

Furthermore, SIGSealTM introduces an innovative Precision Thickness Control to ensure the precise application of adhesive. With this level of precision control, we guarantee a coating as smooth and flawless as a work of art.

Complementary to these high standards, SIGSealTM employs a proprietary AOI process that monitors coating defects in real-time, allowing for immediate corrective action.

Non-contact Coating

Introduction Non-Contact Coating for even adhesive application.

Precision Thickness Control

Ensures impeccable and precise adhesive control.

AOI Process

Real-time monitoring of coating defects during the AOI process.

Strength and Proven Track Record

Tests conducted on coated paper with SIGSealTM Coating Technology on Tyvek® demonstrate superior results in multiple key performance metrics over competing offerings on the market. Notable highlights include exceptional air permeability, consistent heat sealing, excellent tensile strength, uniform adhesive residue distribution, reliable adhesive application, and resistance to yellowing.

Exceptional Air Permeability

SIGSealTM’s precisely engineered adhesive formulation with its porous structure preserves Tyvek®’s inherent breathability, enabling it to serve as an effective sterile barrier.

Uniform Heat Sealing

SIGSealTM’s unique adhesive formulation strikes a balance between breathability and stable sealing strength. This results in superb performance in sealing strength tests, especially when sealing Tyvek® to flexible materials such as PE Film.

Consistent Seal Quality

Our meticulously crafted formula allows for precise control, maintaining adhesive strength lower than the adhesive-to-Tyvek® substrate interface. This makes it easy to peel apart packaging without paper fiber issues, and the adhesive residue is evenly distributed.

Resistance to Yellowing

With the use of selected resins, SIGSealTM effectively mitigates yellowing during the material aging process. It retains its original color and maintains a smooth, wrinkle-free appearance.

”SIGSealTM delivers trusted seal integrity every time. It’s what Tyvek® medical sterilization packaging always needed.”