Innovative Solutions in Materials Science

Unlocking Opportunities with Technological Expertise

As a leading manufacturer of medical sterilization packaging in Asia, SIGMA has 40+ years of industry know-how. Vertically integrated with BenQ Materials, we leverage the Group’s resources to propel innovations to new frontiers.

Amplifying Service Value

We offer end-to-end services for medical device manufacturers, including material selection recommendations, comprehensive material testing, sterilization packaging, and final transportation. Our product verification and process validation procedures adhere strictly to ISO 11607 standards, and our lab quality management system complies with ISO 17025. Through rigorous sterile packaging inspection covering sterilization services, sterile barrier integrity, packaging strength, material properties, compatibility, and stability testing, we ensure our customers' peace of mind.

Drawing upon practical experience, we rigorously simulate transportation conditions, such as temperature variations and vibration levels, to recommend materials for optimal medical device protection. This added service ensures safety and demonstrates our commitment to delivering exceptional value to customers.

Materials Science Foundation

At SIGMA, we harness BenQ Materials’ core technologies to fulfill diverse customer needs. Our advantage lies in crafting eco-friendly water-based coatings with polymer materials.

Precision Coating

Tyvek® coating products

Polymer

Eco-friendly water-based adhesives

Roll-to-Roll

Improved lamination and heat-sealing qualities

Porous Film

Sustainable, breathable sterilization packaging

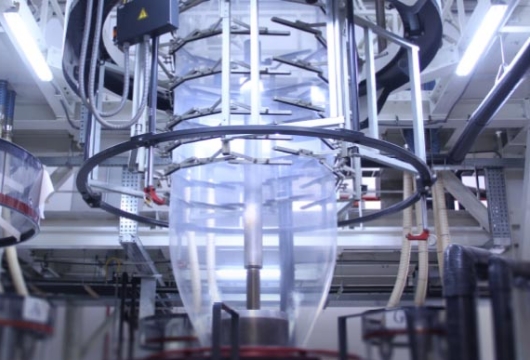

Film Blowing

We utilize BenQ Materials' cutting-edge film-making technologies, featuring a seven-layer film blowing machine—a rarity in the medical industry—paired with solvent-free lamination techniques. This dynamic duo produces top-tier medical films for both upper and lower layers of sterilization packaging of medical devices and disposable medical instruments. Our films are versatile, suitable as top layers for automatic packaging machines or integrated with easy-tear layers for Tyvek® sealing, and ensure high uniformity for flat, puncture-resistant products.

1

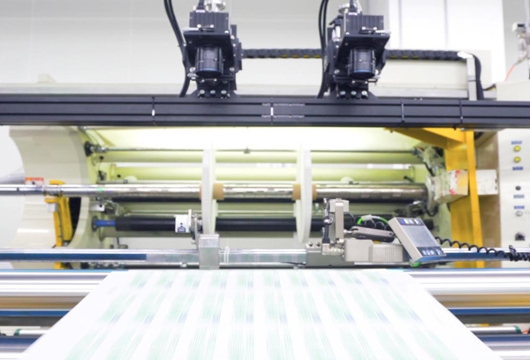

Lamination

Optimized lamination quality and heat sealing through optical film roll-to-roll process.

2

Coating

A suite of advanced adhesive products underpinned by our precision coating technology and proprietary eco-friendly water-based adhesives.

3

Printing

Top-tier European eight-color high-speed printing machines that deliver high-efficiency, high-quality printing services using eco-friendly water-based inks to minimize hazardous solvent emissions.

4

Heat Sealing

High-performance equipment combined with roll-to-roll processes and heat-sealing technology to produce high-quality packaging with tight adhesion, easy tear, and zero paper fiber properties. Our product range includes sterilization rolls, self-sealing pouches, flat pouches, header bags, aluminum foil bags, film pouches, and paper rolls.

5

Smart Factories, Streamlined Efficiency

To improve product performance and maintain stable quality, we implement precise process controls inspired by the electronics industry. This allows us to establish a robust plant management system that merges automation with big data. The outcome? Enhanced process management, superior quality stability, and on-time, every-time delivery for our customers.

Sustainable Design: The Green Power of Materials Science

Our commitment to sustainability extends from product design and manufacturing to daily operations. We use solvent-free formulations, resource-efficient processes, and solar power to minimize our environmental impact.

Green product development

We prioritize sustainability from the outset, designing products that not only meet but exceed recycling standards.

Solvent-free processes

We use 100% water-based inks for printing and solvent-free lamination.

Waste reduction

Waste ink treatment machines recycle up to 90% of the wastewater from the printing process, significantly cutting waste ink from 10 to 1 ton per month.

Decarbonization

With the use of solar power in our plants, approximately 19.03 tons of carbon emissions are reduced annually. Additionally, local procurement mitigates our carbon footprint.