Global 2023-08-31

Why is Tyvek® So Popular in Medical Packaging?

The popularity of Tyvek® as a packaging material is evident in its wide industrial application for medical devices, healthcare, and pharmaceuticals.

With its outstanding microbial barrier properties, lightweight nature, exceptional puncture resistance, tear resistance, and recyclability, Tyvek® is the preferred choice among healthcare professionals and hospitals. Tyvek® stands out as an ideal material for medical packaging, effectively ensuring the safety and stability of medical devices.

Tyvek® comes in various styles suitable for medical packaging. Here are some commonly used ones:

- Tyvek® 1073B: The most commonly used style, it is known for its exceptional physical strength and microbial barrier performance and is an ideal choice for medical devices and pharmaceutical packaging.

- Tyvek® 1059B: Lighter than Tyvek® 1073B, this style is well-suited for packaging relatively small-sized and smooth-edged medical devices. Together with Tyvek® 1073B, Tyvek® 1059B is part of the Tyvek® 10 Series and is also used in pharmaceutical applications.

- Tyvek® 2FS™: Lighter than the Tyvek® 10 Series, it is suitable for form-fill-seal packaging.

When selecting Tyvek® material for medical packaging, SIGMA meticulously considers the specific protective features needed for different medical devices. We recommend choosing the appropriate style based on the specific packaging requirements, medical product characteristics, and a clear understanding of the properties of Tyvek®.

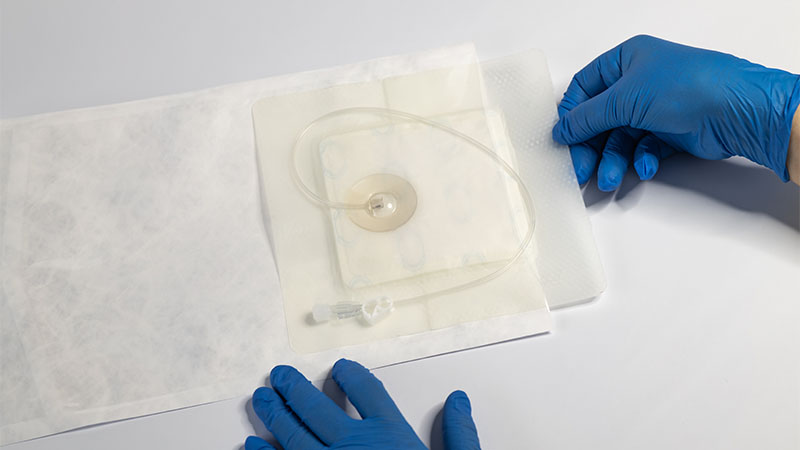

SIGMA's Tyvek® flat/3D individual pouches are made of Tyvek® heat-sealed with a transparent medical film for easy identification of the contents. They are suitable for EO, Plasma, and Gamma sterilization. A variety of sizes are available for packaging various types of medical products.

SIGMA utilizes high-speed eight-color printing machines and environmentally friendly water-based inks to provide accurate, safe, and customized printing on Tyvek®. This printing complies with international regulations such as FDA, EN 868, ISO 11607, and ISO 11140-1.

Product features:

- Provides an effective sterile barrier to prevent cross-contamination of devices.

- Utilizes professional Tyvek® with breathable, bacteriostatic, waterproof and leak-proof qualities.

- Utilizes non-toxic ink and anti-staining technology to make the film transparent and easy for users to identify the content.

- Tough sealing edge prevents bursting after sterilization and maintains seal integrity.

Applications:

- Suitable for low-temperature and ultra-low-temperature surgical instrument packaging.

- Medical surgical consumables and special materials packaging.

- Endoscopic sterilization bags.

Technical Specifications:

| Tyvek® Flat Sterilization Pouches | Upper | Bottom web | Specifications | Sterilization methods | ||

| Style number | Structure | Thickness (um) | Width (mm) | Length (mm) | ||

| 2FS | PET/PE | 52 & 72 | 30~800 | 50~1000 | E.OPlasma Gamma | |

| 1059B | ||||||

| 1073B | ||||||

| Tyvek® Gusseted Sterilization Pouches | Upper | Bottom web | Specifications | Sterilization methods | ||

| Mode number | Structure | Thickness (um) | Width (mm) | Length (mm) | ||

| 2FS | PET/PE | 52 & 72 | 50~800 | 100~1000 | E.OPlasma Gamma | |

| 1059B | ||||||

| 1073B | ||||||

SIGMA maintains the highest level of management control at every stage of product development, design, and quality inspection. With extensive experience in custom manufacturing, we cater to the diverse customization requirements of our customers.

Tyvek® is a trademark or registered trademark of DuPont de Nemours, Inc.